The Best Custom Boat Lines, Custom Colored Ropes, & Special Assemblies made to Your Specifications Denver Rope through our partnership with DSR Corporation is proud to offer Custom, Made-to-Order, Single Point Mooring Hawser Assemblies

We custom assemble all types of Mooring Lines, Dock Lines, Anchor Lines, Mooring Hawsers, Towing Lines, Towing Hawsers, Towing Bridles, Winch Lines, and Recovery Tow Ropes using the best materials and methods the industry has to offer. All our lines are custom made-to-order per the customer’s specifications. Please consider the information below in advance of email ing us with your Request For Quotation. Denver Rope is a factory direct—wholesale distributor for Miami Cordage located in Miami, FL. A family run business serving the marine industry since 1965.

SPM Hawser RFQ’s should be Accompanied with Detailed Specifications to include Engineered Drawings when available.

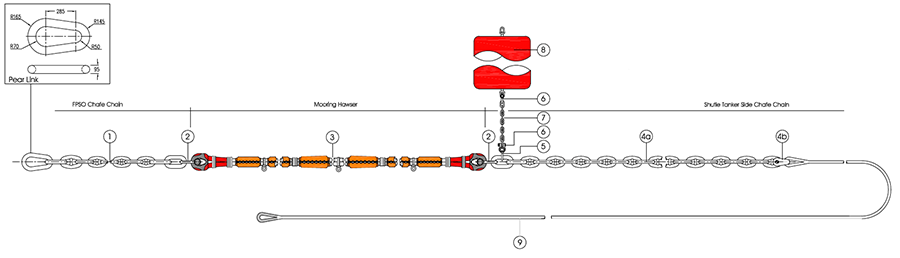

Single Point Mooring Hawsers are typically used in the Oil & Gas Industry whereby an Oil Tanker (or any ship) can be securely moored to an offshore Floating Production Storage Offloading Facility (FPSO), offshore Floating Storage and Offloading Unit (FSO), Tanker Buoy as depicted above.

Another application for Single Point Mooring Hawsers is for Ocean Floor Anchoring Systems. Deep Sea Mooring Hawsers are highly specialized, performance engineered, and manufactured.

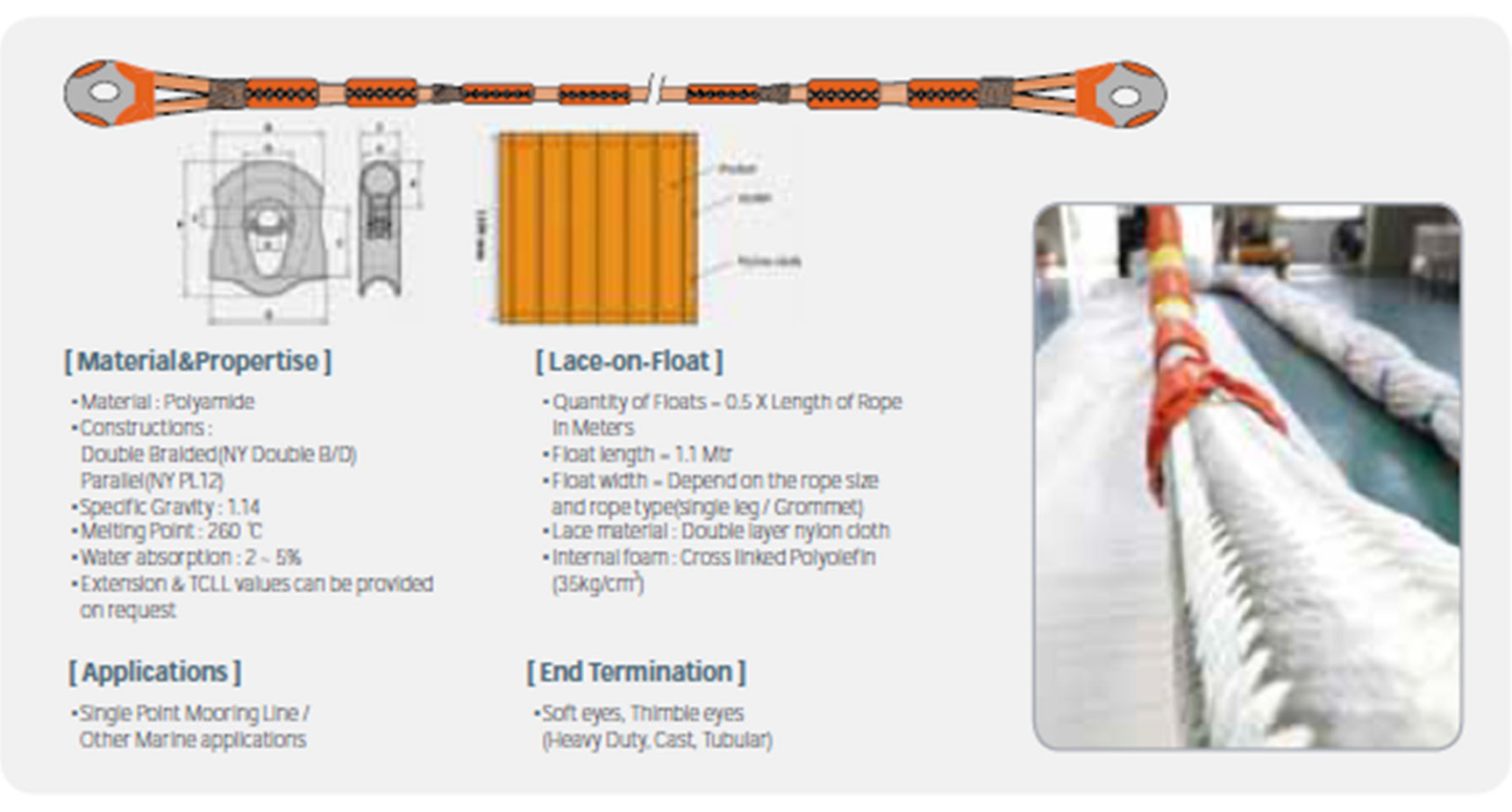

Please consider the following General Information regarding SPM Hawser Design Specifications and Features:

- Typical SPM Hawser Rope Fiber Materials include Nylon, Polyester, Polypropylene / Polyester fiber blend

- Typical SPM Hawser Rope Construction include 8-Strand, 12-Strand, and Double Braids

- Typical SPM Hawsers are generally in the range 45m—100m + custom in length

- Maximum SPM Hawser Single Leg Rope Diameter = 7-0” or 22” circular

- Typical SPM Hawsers are either Single Leg or Double Leg / Grommet style

- Typical SPM Hawsers can be supplied with Soft Covered Eyes and or Hard Thimble Eyes

- Typical SPM Hawser Thimbles styles include Cast, Tubular, Bell Mouth, etc

- Typical SPM Hawsers can be provided with Lace-on-Floats and or Orange Polyurethane / Inherent Buoyancy

- Lace-on-Floats and Orange Polyurethane provide the required buoyancy, abrasion resistance, and fiber protection

- Typical SPM Hawser Available Quality Certificates include: Loyds, BV, ABS / DNV

- SPM Hawsers are Manufactured and Tested in accordance with OCMIF 2000 Guidelines

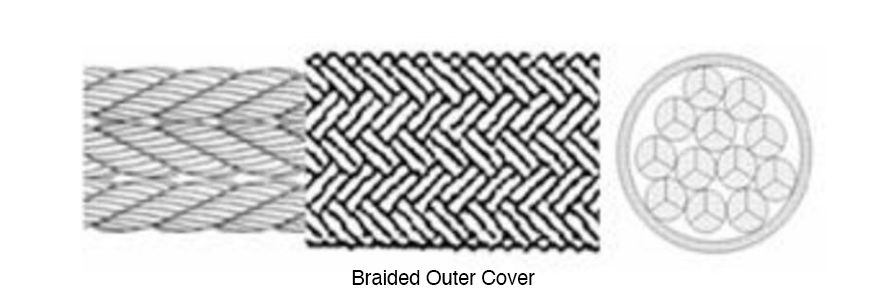

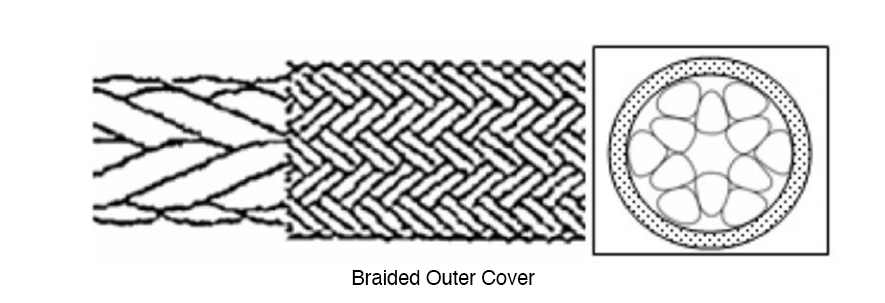

SPM (Single Point Mooring) The NWBS and energy absorption performance of hawsers can deteriorate due to certain influences and factors such as service life, cyclic load history, hawser type, construction, environmental conditions, and handling between use. Since the construction and type of material used to construct an SPM rope varies from location to location and the operational procedures will constantly change, DSR produces our NY Double BD from Polyamide Nylon 66. Nylon 66 has the highest energy absorption performance as compared to other synthetic fibers such as polyester, polyethylene and polypropylene. In addition, Nylon 66 exhibits better yarn-on-yarn abrasion performance. Using DSR’s NY Double B/D, you can expect superior service life in all marine applications including SPM Hawsers. Consider the two tables below for Single Leg style SPMs. The table on the top is for Single Point Mooring Hawsers provided in Double Braid Nylon Construction. The table on the bottom is for Single Point Mooring Hawsers provided in 12-Strand Plaited Nylon Construction. Both ropes have an inner core of Nylon 66 fiber and an outer braided cover of Nylon 6 fiber.

Double Braid Nylon SPM Table

| Dia | Circ | Weight | Breaking Strength | ||

|---|---|---|---|---|---|

| In Air | Submergerd | NDBS | NWBS | ||

| mm | Inch | Kg/100m | Kg/100m | Ton | Ton |

| 48 | 6 | 153 | 15 | 57 | 51.2 |

| 56 | 7 | 210 | 21 | 76 | 58.2 |

| 64 | 8 | 274 | 28 | 98 | 88 |

| 72 | 9 | 333 | 34 | 122 | 110 |

| 80 | 10 | 400 | 40 | 148 | 133 |

| 88 | 11 | 480 | 48 | 175 | 157 |

| 96 | 12 | 574 | 58 | 208 | 157 |

| 104 | 13 | 588 | 69 | 245 | 220 |

| 112 | 14 | 788 | 79 | 280 | 251 |

| 120 | 15 | 929 | 94 | 325 | 292 |

| 128 | 16 | 1,038 | 105 | 363 | 326 |

| 136 | 17 | 1,200 | 121 | 418 | 375 |

| 144 | 18 | 1,332 | 134 | 460 | 413 |

| 152 | 19 | 1,436 | 148 | 500 | 449 |

| 160 | 20 | 1,523 | 164 | 550 | 494 |

| 168 | 21 | 1,790 | 181 | 605 | 543 |

| 176 | 22 | 1,980 | 200 | 673 | 604 |

12-Strand Plaited Nylon SPM Table

| Dia | Circ | Weight | Breaking Strength | ||

|---|---|---|---|---|---|

| In Air | Submergerd | NDBS | NWBS | ||

| mm | Inch | Kg/100m | Kg/100m | Ton | Ton |

| 48 | 6 | 153 | 15 | 65 | 58.1 |

| 56 | 7 | 210 | 21 | 82 | 73.2 |

| 64 | 8 | 274 | 28 | 107 | 96.1 |

| 72 | 9 | 333 | 34 | 134 | 120 |

| 80 | 10 | 400 | 40 | 158 | 142 |

| 88 | 11 | 480 | 48 | 194 | 174 |

| 96 | 12 | 574 | 58 | 234 | 211 |

| 104 | 13 | 588 | 69 | 275 | 247 |

| 112 | 14 | 788 | 79 | 316 | 284 |

| 120 | 15 | 929 | 94 | 365 | 328 |

| 128 | 16 | 1,038 | 105 | 408 | 366 |

| 136 | 17 | 1,200 | 121 | 467 | 419 |

| 144 | 18 | 1,332 | 134 | 520 | 467 |

| 152 | 19 | 1,436 | 148 | 571 | 513 |

| 160 | 20 | 1,523 | 164 | 627 | 563 |

| 168 | 21 | 1,790 | 181 | 683 | 613 |

| 176 | 22 | 1,980 | 200 | 754 | 677 |

- Manufactured and tested in accordance with the OCIMF 2000 Guidelines

- NDBS: New Dry Breaking Strength / NWBS: New Wet breaking Strength

- Specific gravity of swa water assume 1,025

- Other sizes are available upon request (Maximum production size -Dia. 300mm)

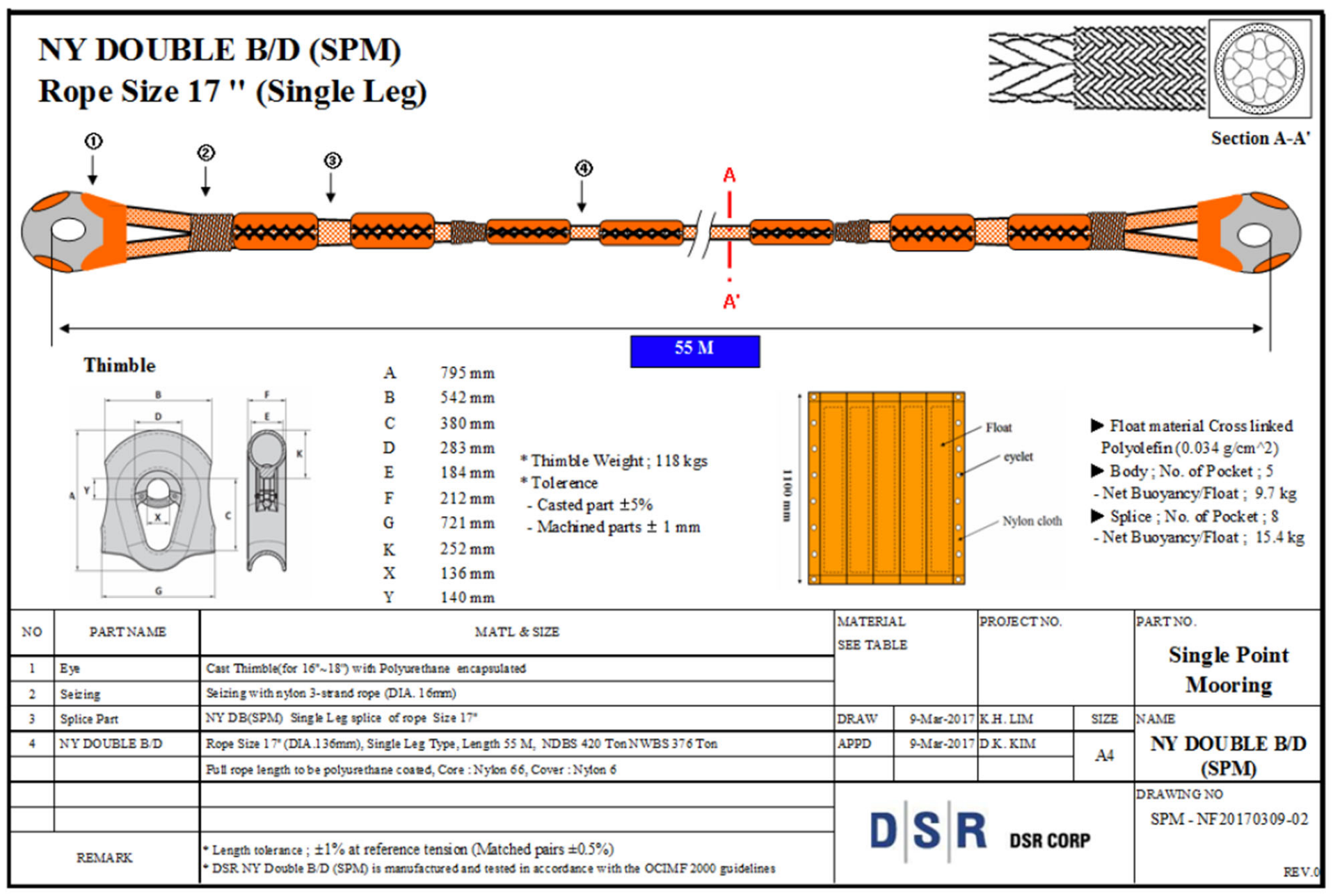

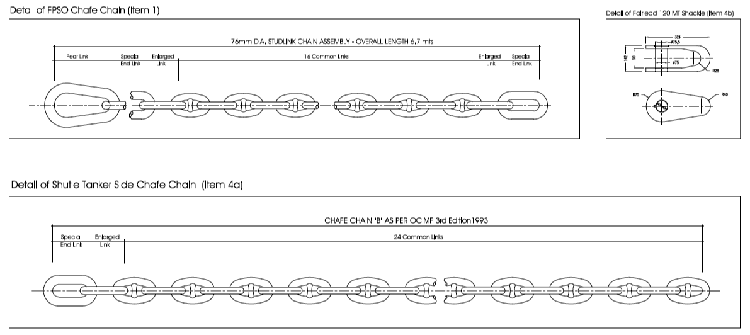

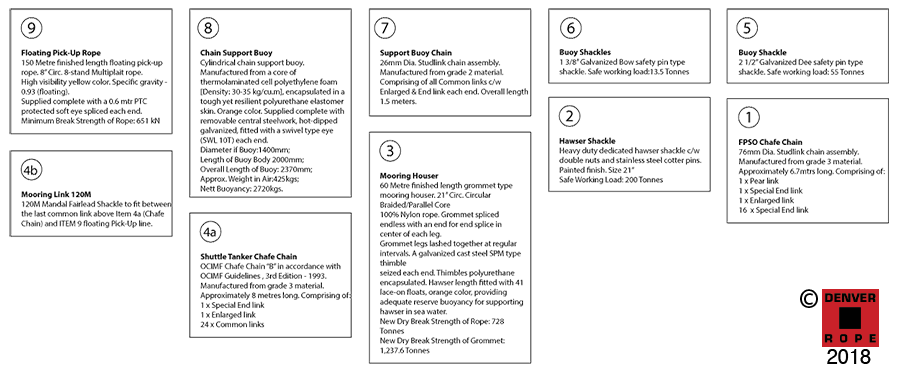

Denver Rope — Single Point Mooring Hawser Diagrams Consider the two diagrams below for SPMs. The top diagram depicts a Single Point Mooring Hawser provided in Single Leg Style. The bottom diagram depicts a Single Point Mooring Hawser provided in Double Leg or Grommet Style. Both SPMs are depicted with Lace-on-Floats and with Orange Polyurethane encapsulation at the rope ends and thimble splices. The last two diagrams depict 12-Strand Plaited Construction and Double Braid Construction, both with an outer braided cover.

Single Leg SPM

Double Leg / Grommet SPM

The picture above shows a Single Point Mooring Hawser provided with Lace-on-Floats and Yellow Chafe Guard protecting the white rope between the floats.

white rope between the floats” width=”1922″ height=”1322″> The two pictures above show a Single Point Mooring Hawser provided with Lace-on-Floats, Yellow Chafe Guard protecting the

white rope between the floats, and Orange Polyurethane Encapsulation protecting the rope at the thimble splice. The thimbles are cast tubular type thimbles also provided with orange polyurethane encapsulation. The picture on the left is a Single Leg Style SPM Hawser and the picture on the right is a Double Leg / Grommet Style SPM Hawser.

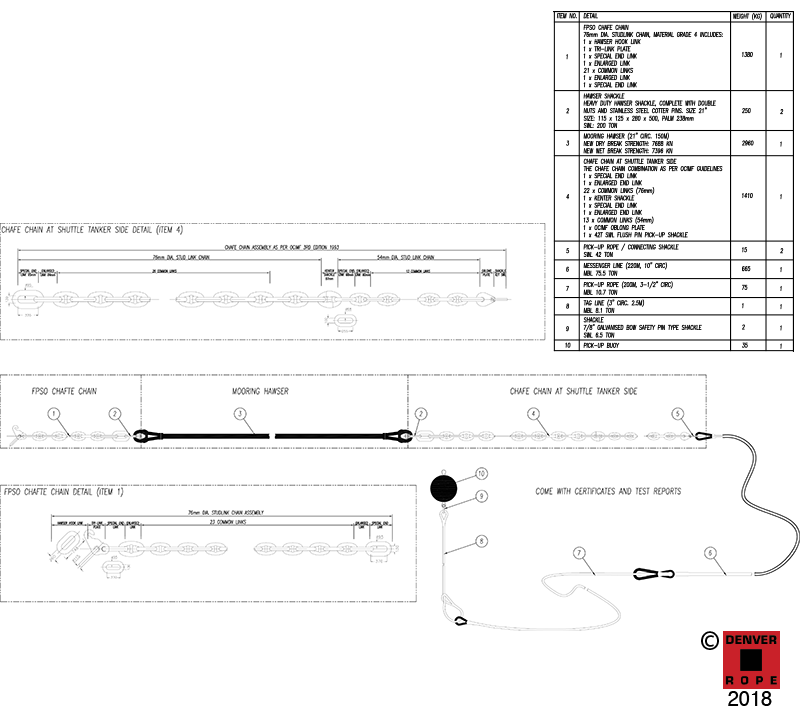

Above is an example of an Engineered Drawing for a Single Point Mooring Hawser (single leg type) provided with Lace-onFloats and Orange Polyurethane Encapsulation protecting the rope at the thimble splice. The thimbles are cast tubular type thimbles also provided with orange polyurethane encapsulation.

- Manufactured by DSR in Korea in accordance with ISO 900:2008, Lloyd’s certified

- Mill Test certificate provided with each line

| Part# | Nominal Diameter

|

Circ (in) | Tensile Strength (lb) | |||

|---|---|---|---|---|---|---|

| PPR8SD2720 | 2 | 48 | 6 | 67,200 | ||

| PPR8SD214720 | 2-1/4 | 56 | 7 | 78,000 | ||

| PPR8SD212720 | 2-1/2 | 65 | 7.5 | 91,500 | ||

| PPR8SD258720 | 2-5/8 | 68 | 8 | 103,500 | ||

| PPR8SD3720 | 3 | 72 | 9 | 135,000 | ||

| PPR8SD314720 | 3-1/4 | 80 | 10 | 171,000 | ||

| PPR8SD4720 | 4 | 100 | 12 | 243,000 | ||

Single Point Mooring Hawser - Example One Diagram

Single Point Mooring Hawser - Example Two Diagram

Conversion Factors and Information

1 inch = 25.4 mm

12 inches = 1 foot

1 foot = 304.8 mm

1 meter = 3.28 ft

Circumference of a Circle

Circular = PI x Diameter

Weight

1 Pound = 0.4536 kG

1 kG = 2.2046 lbs

Force

1 Newton = 0.2248 lbs

1 kN = 224.8 lbs

Standard Hawser Lengths & MBS/WLL

50 ft / 100 ft / 300 ft / 600 ft / 720 ft / 900 ft / Custom

Where 1 Fathom = 6 feet

Minimum Breaking Strength (MBS) to Working Load Limit (WLL)

WLL for Very Conservative = MBS/10

WLL for Standard Conservative = MBS/5 (Denver Rope Selection)

WLL for Less Conservative = MBS/3

WLL = Engineered Calculation